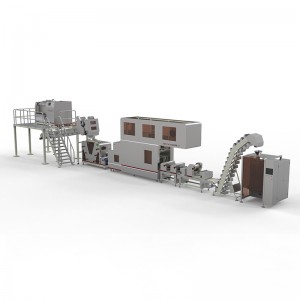

Noodle Equipment-Bundling Solid Bags production line

Low output, Large labor, Large energy consumption, and it is difficult to form large-scale production.In response to this situation, our company has developed a fully automatic production line for multi-bundling Solid bags.The whole production process is automated from the Noodle Cutting, Noodle conveying , the quantitative packaging, and the storage of the finished products in the large bags. Increased production, reduced labor, reduced energy consumption, and created conditions for large-scale production of such products. Packing speed is fast, up to 50 packs / minute.

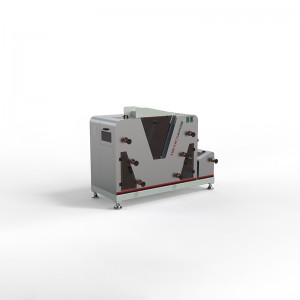

Smart connection details

1. production line Contains:

High precision Automatic Noodle cutting machine-Conveyor Type Feeding System-Weighing Machine-Bundling Machine – Bundling Conveyor -intelligent material handling device-automatic propulsion machine-M-shape bag Packing machine – double rejection automatic checkweigher – Plastic Bag Flat Pocket – robot palletizer.

2. production line process:

The whole rod Noodle from the drying room enters the high-precision cutting machine and is intelligently cut according to the preset length.The cutted Scattered Noodle into the weighing machine stations through the intelligent Conveyor Type Feeding System.After accurate weighing by each weighing machine, it will enter the bundling machine station for bundling, and the bundled materials will be sent to the intelligent material handling device by the bundling conveyor. After the material is controlled and stretched by the intelligent material handling device, the picking mechanism is used. The automatic propulsion machine is picked up according to the predetermined number of packages, and is automatically pushed into the M-shape bag packaging mechanism bag by the automatic propulsion machine, and is packaged by the M-shape bag packaging machine. After the packaging, the single-bag finished product is subjected to weight inspection by double-checking the automatic checkweigher, and the qualified products are put into the plastic bag flat pocket bagging machine for large bag packaging. The packaged large bag finished product is sent to the palletizing area via the finished conveyor, and is palletized by the palletizing robot, and then sent to the finished product warehouse to complete the entire production process.

3. production line economic benefit analysis:

1 For different brands of noodle products, the quality of the flour used and the production process are not much different. However, the sales price of the products has a big difference. In addition to the difference in brand and taste, the main factor that distinguishes the grade of the noodles is the packaging form of the noodles. Habitually, the conventionally noodle products packaged on the market are divided into seven categories: ultra low, low, middle, low, mid, Mid high, high and super high.

1. Ultra-low-grade packaging generally refers to 2.5kg ordinary tote bag or 2.5kg roll paper package. There are also some uncoated roll paper packaging products that fall into this category. The retail price of this products is generally below 3,000 yuan / ton;

2.Low-end packaging refers to the product of 1000 g or less of loose plastic packaging products or roll paper packaging and film processing. The retail price of this products is generally around 3,500 yuan / ton;

3.The middle and low-end packaging refers to the bulk M-shape bag plastic package products below 1000 grams. The retail price of this products in the market is generally around 4,500 yuan / ton;

4.The mid-range packaging is a specified amount of large gram heavy bundling packaging products. Weight 200-250 g / bundle, 4-5 bundles / bag, weight between 800-1000 grams/bag. The retail price of this products is generally 5000-6000 yuan / ton. Individual products in the form of M-shape bags can reach 7,000 yuan / ton. Because the film price is not much different from the ordinary plastic package, it only increases the cost of the bundle of 200-300 yuan per ton, so it has a very high profit margin.

5.Medium and high-grade packaging is a specified amount of small gram bundling packaging products. The weight is 75-150 g/bundle, 4-5 bundles/bag, and the weight is between 300-600 grams/bag. The retail price of this products is generally around 8,000 yuan / ton.

6.High-grade packaging refers to the replacement of the outer packaging of the medium-to-high-grade quantitative small-weight bundling packaging products into the body bag packaging form. The retail price of the market soared to 8,000-10,000 yuan / ton.

7.Ultra-high-end products are small-sized products required for children’s noodles and special groups after being bundled in a specified amount. Or other packaging like wooden boxes, paper tubes and other special packaging forms. Due to the low sales of these products, Now haven’t the mass production.

2.The multi-Weighing Bundling M-shape bag automatic production line (with the standard eight-station as an example), the degree of automation is significantly improved

Compared with the traditional manual production line, the curved intelligent feeding system can save 2 labors per shift; the packaging machine can replace the manual prefabricated bags, saving 4 people per shift; double elimination of the automatic checkweigher can save labor 1 per shift. People; plastic bag flat pocket bagging machine can save 1 person per shift; robot palletizer can save 1 person per shift; statistics, total can save 9 people per shift.

Our third-generation multi-Weigher Bundling M-shape bag automatic production line is an industrial automation production line for advanced quantitative packaging at China and abroad,It can produce large-weight quantitative packaging products (800-1000g/bag, 200-250g/bundle), also can be compatible with small-weight quantitative packaging products (300-600g/bag, 75 -150g/bundle) ,it is the secret weapon for noodle manufacturers to open the mid- to high-end market.Moreover, the equipment has high flexibility in configuration, the Noodle manufacturer can choose according to the production capacity of the production line and the market sales. You can choose either Six-Weigher or eight-weigher Full Automatic Bundling and M-shape bag packing machine,or even you can choose the ten-Weigher Full Automatic Bundling and M-Shape Bag packing machine.Our Turkey customer buy the twelve – weigher Full Automatic Bundling and M-shape bag packing machine. We have more than 50 customers use this Equipment at China.We have Turkey, Canada, Myanmar, India and Taiwan customers using our Multi-weigher bundling packaging line,long-term procurement.