Rice Noodle Production Line

-

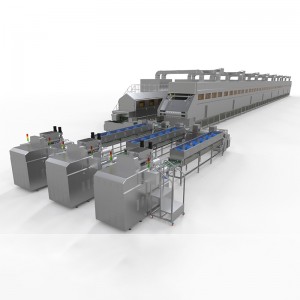

Fully Automatic Half Dry Rice Macaroni production line

Product model:QZDSF-1000

Summary information:This production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc., and meets the full-automatic process from rice loading to packaging. The production line products use rice as the main raw material, with a water content of 60-68%.

Applicable products:Rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc.

Production location:Qingdao China

-

Fully Automatic Fresh Wet flat Rice Noodle production line

Product model:QZDXHF-1000

Summary information:

This production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc., and can meet the full automatic process from rice loading to packaging.

Applicable products:

Rice noodle products such as fresh wet flat rice noodles, steamed vermicelli roll, and sheet jelly.

Production location:Qingdao China

-

Multi functional Dry Rice Noodle Cake production line

Product model:QZDKZGF-750

Summary information:This production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc. It meets the full process from rice feeding to forming, cutting and drying. With rice as the main raw material, the water content is 14-15%, which meets the product demand of 18 months of shelf life after fresh-keeping treatment.

Applicable products:Rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc.

Production location:Qingdao China

-

Fully Automatic Snail Rice Noodle production line

Product model:QZDLSF-750

Summary information:

The production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc., meeting the fully automatic process from rice feeding to forming and cutting. The production line products use rice as the main raw material, with a moisture content of 14-15%, meeting the product demand of 18 months of shelf life after preservation treatment.

Applicable products:Rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc.

Production location:Qingdao China

-

Fully Automatic Straight Dried Rice Noodle production line

Product model:QZDZTMF-750

Summary information:

The production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc., and meets the fully automatic process from rice mixing to finished products. With rice as the main raw material, the water content is 14~15%, the shelf life is 18 months, and the diameter is 0.8mm-2.0mm.

Applicable products:

Rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc.

Production location:Qingdao China

-

Fully Automatic Straight Fresh Wet Rice Noodle production line

Product model:QZDZTXF-1000

Summary information:

This production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc. It meets the full automatic process from rice feeding to forming and cutting.

Applicable products:

Production line products; rice as the main raw material, with a moisture content of 66% to 70%, and are packaged in composite film bags to meet the product demand for a shelf life of 6 months after fresh-keeping treatment.

Production location:Qingdao China

-

Full-automatic fresh rice noodle production line

Product introduction Using rice as the main raw material, it produces fresh wet rice noodles with a moisture content of 66% to 70%. It is packaged in a composite film bag and can be stored for 6 months after preservation. Technological Process Mixing rice → micro-fermented soaked rice → filtering water → crushing rice → mixing flour → automatic feeding → maturing and extruding wire → cutting off fixed strip → checking weight → conveying → automatic boxing → aging → softening → Shapi... -

Intelligent Straight Rice Noodle Making Machine Production Line

The Rice Noodle intelligent production line achieves the automation of the whole line without manual assistance of rice soaking, crushing, extrusion, cutting, quantitiveness, sorting into boxes, aging, softening, disinfecting and drying. It greatly reduces the potential dangers of food safety, reduces labor intensity and improves the economic benefits of customers. It makes a breakthrough in the market.

With rice as the main raw material, the water content of the straight rice noodle is 14-15%, and the shelf life can reach 18 months.

Highlights:

1. Product specification: 0.8-2.5mm diameter of dry rice noodle, and the production capacity is 750-780kg / h.

2. 10 hours per shift, 9 hours of production, 15-16 employees per shift, the yield is 14 Tons of straight rice noodles in two shifts.

-

Automatic Rice Macaroni Production Line

With rice as the main raw material, the water content of the rice macaroni is 14-15%, and the shelf life can reach 18 months.

1. Product specification: 4mm, 6mm and 8mm. The production capacity is 750kg / h.

2. 10 hours per shift, 9 hours of production, 8 employees per shift, the yield is 14tons of rice macaronis in two shifts. -

Automatic Semi Dry Rice Noodle Making Machine Production Line

With rice as the main raw material, the water content of the semi dry rice noodle cake is 42-45%. Packaged in composite film bags, the shelf life after preservation treatment can reach 6 months.

1. Product specification: 160-200g / bag, 4320 bags / h, and the production capacity is 650-850kg / h.

2. 10 hours per shift, 9 hours of production, 13 employees per shift, the yield is 14T of semi dry rice noodles in two shifts.