One of Hottest for Moringa Noodles Packaging Line - Automatic Flat Bag Packing Machine – Hicoca

One of Hottest for Moringa Noodles Packaging Line - Automatic Flat Bag Packing Machine – Hicoca Detail:

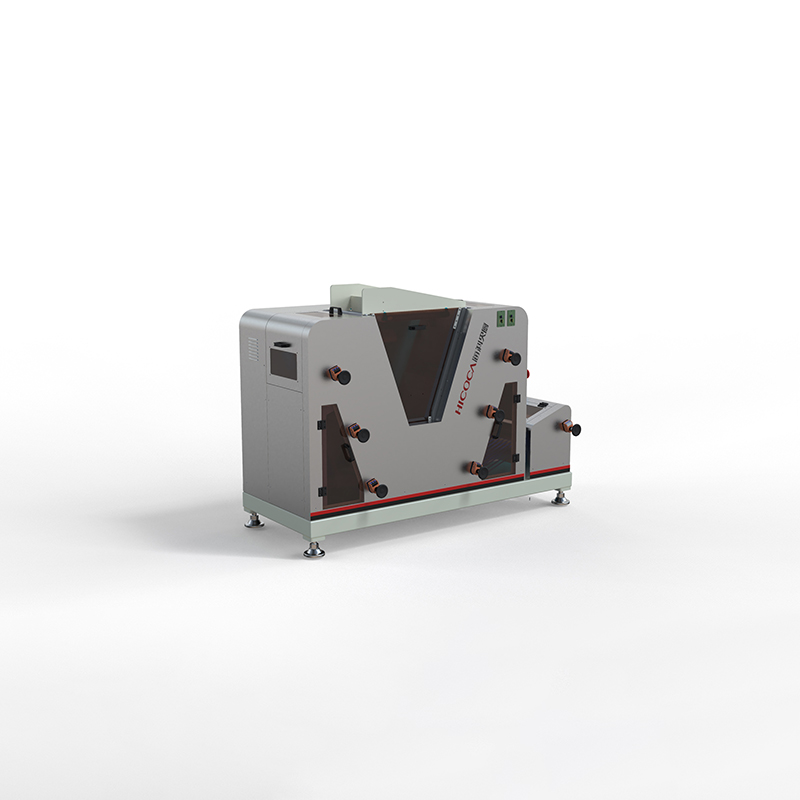

Automatic Flat Bag Packing Machine

Contents:

1. Bagging machine: one set

2. Unloading machine: one set

Application:

The machine is suitable for the flat bag collective packing of single bags of products with long strips such as stick noodle, spaghetti, rice noodles, vermicelli and Yuba. The whole process of fully automatic flat bag packing is completed through automatic feeding, sorting, bagging and sealing.

Main Specs:

| object | packaged noodle, Spaghetti, pasta,rice noodle |

| packing rate | 3 bags/min |

| packing range | 350~1000g(the weight of a single bag) |

| gas consumption | 30L/min |

| single package weight | 10~20kg |

| single package number | 10~20 bags/package |

| voltage | 220v(380v)/50-60Hz/2.5kw |

| equipment size | 4800*1450*1880mm |

3. The outputting of one device is 40 tons per day, only needing 1 person to manage, saving 2 persons’ labour.

About us

We’re a DIRECT factory specialized in designing and manufacturing full sets of intelligent food production and packaging assembly lines, including intelligent equipments of feeding, mixing, drying, cutting, weighing, bundling, elevating, conveying, packaging, sealing, palletizing, etc. for dried and fresh noodle, spaghetti, rice noodle, incense stick, snack food and steamed bread.

With over 50000 square meters manufacturing base, our factory is equipped with the world’s advanced processing and manufacturing equipments such as laser cutting machining center imported from Germany, vertical machining center, OTC welding robot and FANUC robot. We have established a complete ISO 9001 international quality system, GB/T2949-2013 intellectual property management system and applied for more than 370 patents, 2 PCT international patents.

HICOCA has over 380 employees, including over 80 R&D personnel and 50 technical service personnel. We can design machines according to your requirements, help to train your staff and even send our engineers & technical staff to your country for after-sales service.

Pls feel free to contact us if you’re interested in any of our products.

Our products

Exhibition

Patents

Our Foreign customers

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for One of Hottest for Moringa Noodles Packaging Line - Automatic Flat Bag Packing Machine – Hicoca , The product will supply to all over the world, such as: Namibia, Denver, Chile, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.