On December 9, five new technologies and new products of HICOCA’s staple food intelligent equipment passed the appraisal.

The experts of the appraisal committee agreed that the “Flake Composite Calender”, “Rice Noodle Weighing Machine” and “Bionic Hand-pulled Noodle Intelligent Production Line” have reached the international leading level; advanced level.

The New Product and New Technology Appraisal Meeting will be reviewed by Qingdao University, Qingdao University of Science and Technology, as well as experts and professors in the industry.

At the meeting, the Appraisal Committee listened to the R&D and innovation of new products and new technologies by the project leaders, reviewed relevant technical materials, watched product pictures and videos, reviewed relevant materials, and questioned relevant details and applications. At the same time, it put forward guiding opinions on the improvement of new product research and development and application materials, and fully affirmed the research and development process and implementation effect of new products and new technologies.

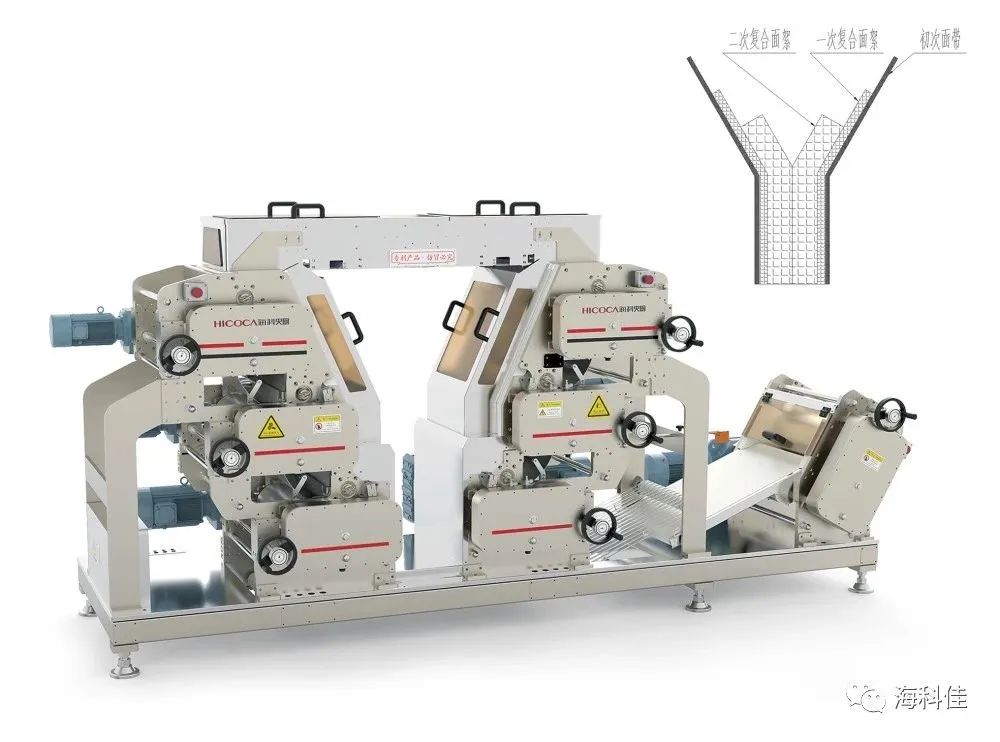

1 Sheet-wax compound calender – Equipped with 7 pairs of high chromium alloy rollers, the whole is V-shaped, with compact structure and reasonable layout. Completing the 3-time composite process of flakes and noodle strips, the pressed noodle strips have different densities in the longitudinal section, and the density decreases sequentially from the outside to the inside, naturally forming six layers of interlayers with different densities, making the noodles loose on the inside and tight on the outside. better. During the cooking process, the inside and outside of the noodles can be cooked simultaneously, shortening the cooking time by about 60 seconds.

According to the test data of texture analyzer, compared with the Japanese noodle composite process and traditional manual process, the chewiness is 1.06% and 2.82% higher, and the elasticity is 1.6% and 9.8% higher. Haikejia recruited 200 people from all over the country After a trial, the taste is stronger and smoother, the hardness is moderate, and the elasticity is stronger. The verification results are consistent with the data of Japanese noodle making technology, which is superior to the traditional domestic handicrafts and has achieved a technological breakthrough.

2 Rice Noodles Weighing Machine – HICOCA’s patented product, suitable for weighing rice noodles with a length of 180-260mm. Using “three-level weighing technology”, the weighing accuracy can be controlled between ±2g-±5g.

1. Through the progressive movement structure, the rice noodles are partitioned and sorted to eliminate the cross network.

2. Adopt the active conveying method to push the rice noodles and other strip materials forward to achieve the purpose of neat and stable feeding.

3. By arranging multiple up and down blocks at intervals, it can realize the inclined up and down movement at a certain angle, and carry out progressive multi-layer sorting of rice noodles, realizing the function of continuous flow of rice noodles.

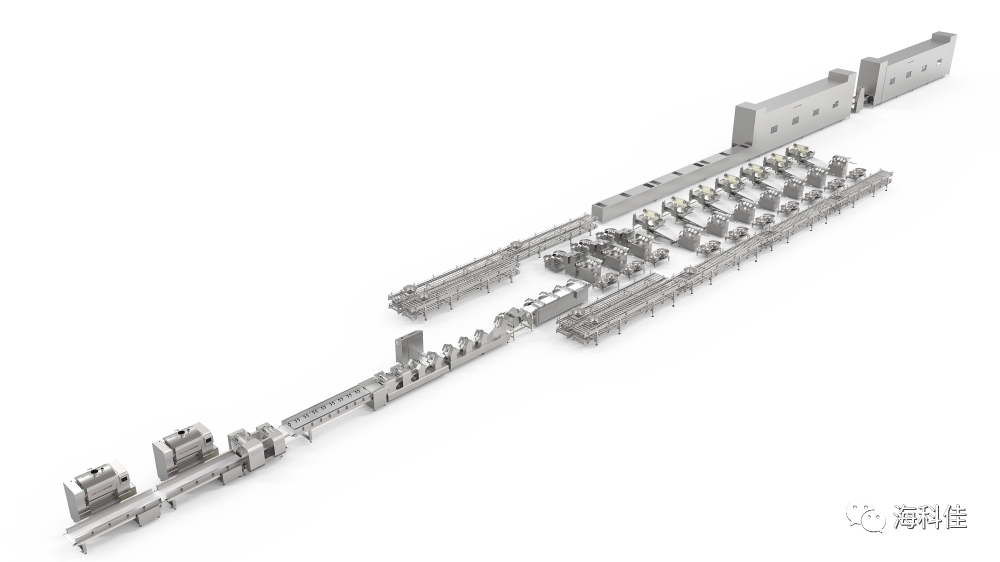

3 Bionic hand-pulled noodles intelligent production line – the first innovative product independently developed and manufactured at home and abroad. The production line goes through the processes of kneading noodles, proofing, tapering and rolling, cutting into strips, finely pulling on the rod, step-by-step lifting, drying and cutting. , realize the traditional production of hand-pulled noodles, and provide intelligent services for enterprises to meet food safety and high-end product transformation.

The hand-pulled noodles are proofed many times, and the gluten network is fully formed. The noodles are rotated many times, so that the gluten network forms a tough gluten structure, and the noodles are more tenacious. The noodles are stretched and proofed many times, so that the starch is evenly attached to the gaps in the gluten network, making the noodles more springy and smooth.

HICOCA ‘s bionic hand-pulled noodle intelligent production line has advanced technology, high degree of intelligence, simple operation, smooth production, and high production capacity. It is an advanced equipment that breaks through various constraints in the production of hand-pulled noodles.

4 The high-speed bionic kneading machine adopts the artificial vertical cross-folding and rolling form, and the single pressing dough is 10-50kg. During the kneading process, the gluten network is distributed in a network shape, the gluten network and starch granules are more closely combined, and the internal structure of the dough is uniform and stable. , Play a key role in improving the taste of steamed buns.

Calendering and folding times can be set freely on the touch screen and adjusted automatically. Equipped with a powder spreading device, it can realize automatic powder spreading according to the calendering situation.

The calendered noodle has a finer texture, better proofing and gas retention, and better stability. The steamed product has fine and uniform holes, chewy texture, smooth surface, and good color.

The high-speed bionic dough kneading machine is a patented product of HICOCA, and has won the Best Innovative Product Award in the 19th China Convenience Food Industry.

5 Vermicelli sealing machine – flat bag sealing machine fills the gap in the packaging connection of vermicelli. The equipment runs smoothly and the bagging efficiency is high. The assembly line is directly connected to the palletizing line, which truly realizes intelligent production.

The sealing machine has its own weighing function, and the structure is stable. It can be connected to the palletizer after the flat bag is connected to the front, so that the whole noodle production line realizes unmanned production.

Post time: Dec-13-2022