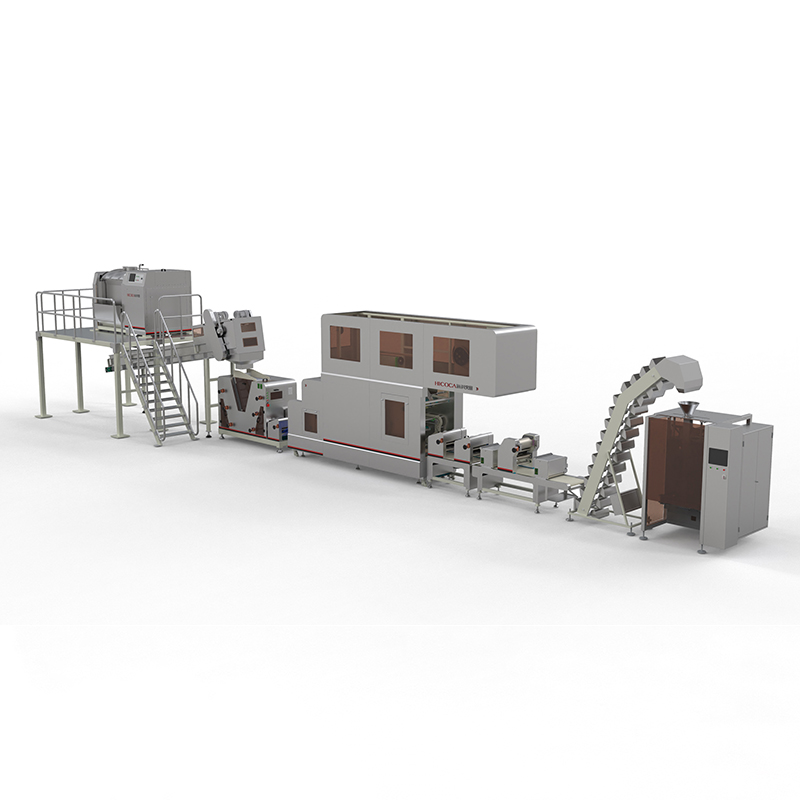

China Cheap price Sliced Noodle Packaging Equipment - Automatic Bag Filling Sealing Packing Machine for Noodle – Hicoca

China Cheap price Sliced Noodle Packaging Equipment - Automatic Bag Filling Sealing Packing Machine for Noodle – Hicoca Detail:

Automatic Bag Filling Sealing Packing Machine for Noodle

Application:

By selecting different measuring instruments, it’s suitable for the packaging of noodle, spaghetti, pasta, rice noodle, vermicelli, liquid, sauce, granules, powder, irregular blocks and other materials.

Machine specifications

| Model | JK-M8-230 | ||

| Filling Volume | 50-2000g | ||

| Speed | 10-45 bags/min | ||

| Bag | Prefabricated bag | ||

| Bag Size | Width: 90-235mm; Length: 120-420mm | ||

| Bag Material | Composite film | ||

| Sealing | Continuous heat sealing (sealing form: by customers’ requirements) | ||

| Sealing Temperature | PID control (0-300 degrees) | ||

| Pressure | Pressure seal | ||

| Printing | 1. Inkjet printing (optional). 2. Hot coding, 3. Hot transfer printing, 4. Lettering |

||

| Bag Feeder | Strap type | ||

| Bag Size Change | 16 grippers can be manually adjusted with one button | ||

| Touch Screen | a. operation button b. speed setting c. parts composition d. electric cam switch e. product number record f. temperature control g. flow j. alarm list: pressure drop, torque limit, main motor overload, abnormal temperature. |

||

| Control voltage | PLC…..DC24V others….AC380V |

||

| Main Components | Component | Brand | Country |

| PLC | Siemens | Germany | |

| Touch Screen | WEIKONG | China | |

| Inverter | Bosch | Germany | |

| Main Motor 2Hp | MAXMILL | Taiwan China | |

| Cylinder & valve | SMC, AIRTEC | Japan or Taiwan China | |

| Electromagnetic Sensor | OMRON | Japan | |

| Main Switch | Schneider | Germany | |

| Circuit protection | Schneider | Germany | |

| Bearing | HRB, LYC | China | |

| Material | a. In contact with product part-SUS304 b. main parts and externally visible parts including the bottom-SUS304 c. body-welded frame (polyurethane coating) d. frame-upper and lower plates (16mm) e. safety protection-acrylic resin |

||

| Machine Weight | Net weight: 1.5-1.7T | ||

| Facility | a. Power: three phase 380V 50Hz 6.5Kw b. Air consumption: 600NL/min. 5-6kgf/cnf c. The compressed air needs to be dry, clean and free of any foreign matter and gas. |

||

Machine characteristics:

1. Easy to operate touch screen menu(10.4″ wide screen)

2. Alarm and menu display, easy to solve machine problems.

3. Change the package size quickly within ten minutes

A: Adjust 16 grippers at the same time with one button

B: The size of the bag feeder is adjusted by the first wheel without tools. That is simple, convenient and fast.

4. Automatic lubrication system, easy to maintain.

5. The machine waits for the feeder to feed.

6. External parts are made of 304 stainless steel and oxidized aluminum alloy.

7. Specially designed sealing strip achieves perfect sealing(One sealing station, one pressure sealing station)

8. Memory retention function (sealing temperature, machine speed, seal width)

9. The touch screen displays over-temperature alarm. Sealing temperature is modularly operated.

10. The spring device ensures easy adjustment of the seal.

11. The specially designed heating device ensures that the bag is sealed firmly without leakage and deformation.

12. Safety protection: Low pressure shutdown safety protection, over-torque frequency conversion alarm shutdown function.

13. Low noise (65db), very low vibration when the machine is running.

14. The machine uses vacuum generator instead of vacuum pump, which significantly reduces the noise.

15. Empty bag removal function prevents empty bags from entering the production line.

Safety functions:

1. No bag, no bag opening – no filling – no sealing function.

2. Heater abnormal temperature alarm display

3. Main motor abnormal frequency conversion alarm

4. Main motor abnormal shutdown alarm

5. The compressed air pressure is abnormal and the machine stops and alarms.

6. Safety protection is on and the machine stops and alarms.

Components:

1. Bag opening sensor

2. Lubricator

3. Colorful touch screen

4. Bag outlet conveyor belt

5. Bag opening plate

6. Air exhaust nozzle

7. Tow-color lamp

8. Air filter

Packing Flow:

Product detail pictures:

Related Product Guide:

Dedicated to strict quality management and thoughtful client services, our experienced staff customers are generally available to discuss your demands and guarantee full client pleasure for China Cheap price Sliced Noodle Packaging Equipment - Automatic Bag Filling Sealing Packing Machine for Noodle – Hicoca , The product will supply to all over the world, such as: Netherlands, Gabon, Uganda, We are very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.