Wholesale Automatic Noodle Making Machine - Full-automatic fresh rice noodle production line – Hicoca

Wholesale Automatic Noodle Making Machine - Full-automatic fresh rice noodle production line – Hicoca Detail:

Product introduction

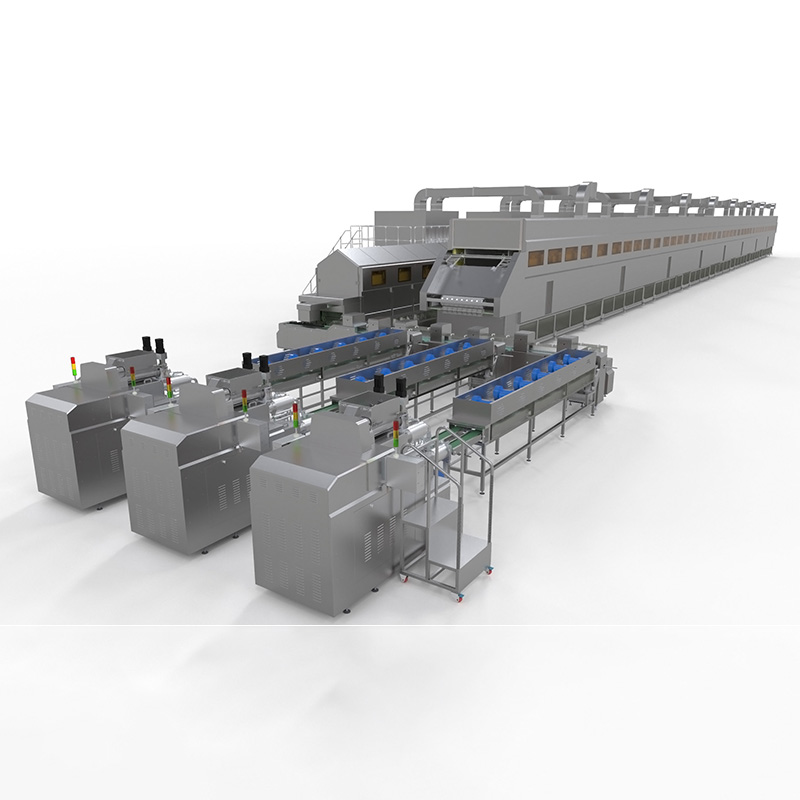

Using rice as the main raw material, it produces fresh wet rice noodles with a moisture content of 66% to 70%. It is packaged in a composite film bag and can be stored for 6 months after preservation.

Technological Process

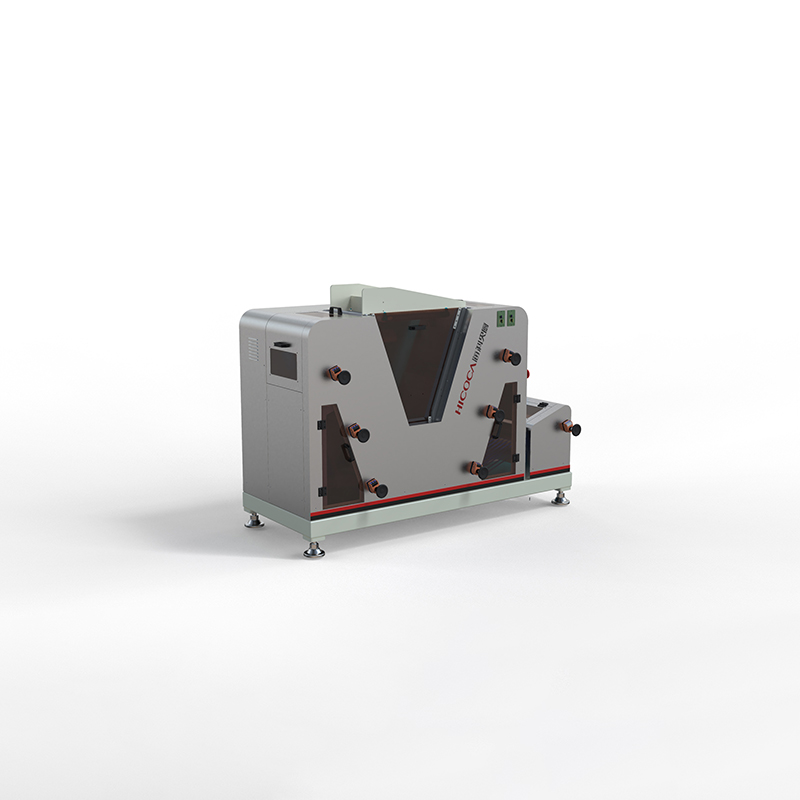

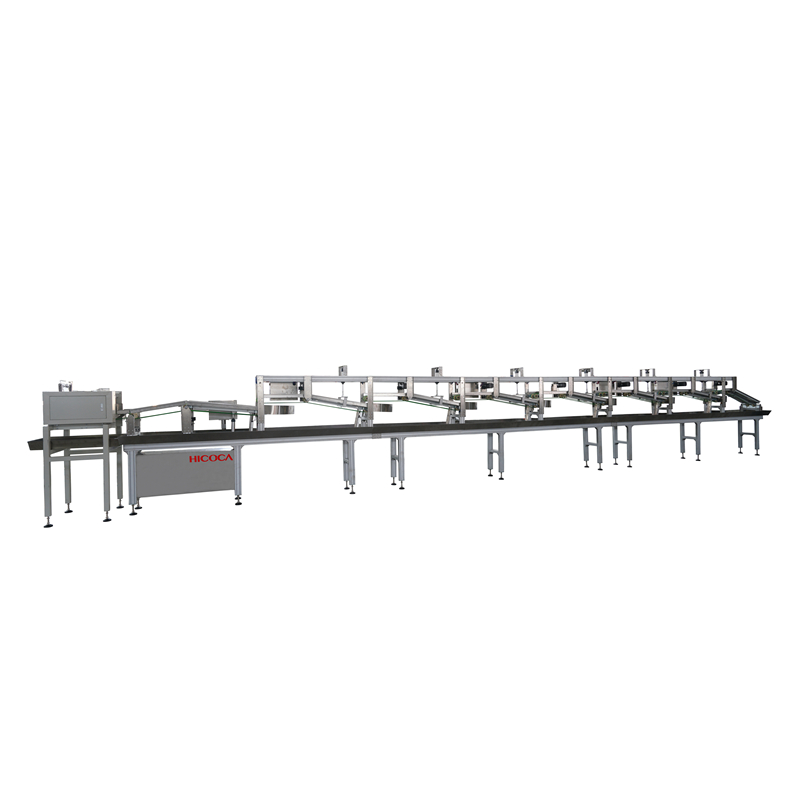

Mixing rice → micro-fermented soaked rice → filtering water → crushing rice → mixing flour → automatic feeding → maturing and extruding wire → cutting off fixed strip → checking weight → conveying → automatic boxing → aging → softening →

Shaping→sterilization→automatic unloading→bag packing→sterilization→finished product.

Machine Highlights

The production specifications are 200-240g/bag, 4320 bags/h, and the production capacity is 0.86-1.04 tons/hour. 10 hours per shift, 9 hours for silk production, 15 employees per shift, 18.7T fresh wet powder for two shifts.

Technical Parameters

| Rated voltage | 380V |

| Water consumption | 8 tons/ton powder |

| Electricity consumption | 400 degrees/ton powder |

| Air consumption | 2.6 tons/ton powder |

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for Wholesale Automatic Noodle Making Machine - Full-automatic fresh rice noodle production line – Hicoca , The product will supply to all over the world, such as: moldova, Southampton, Jamaica, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

Write your message here and send it to us