HICOCA helps manufacturers cut costs and boost efficiency!

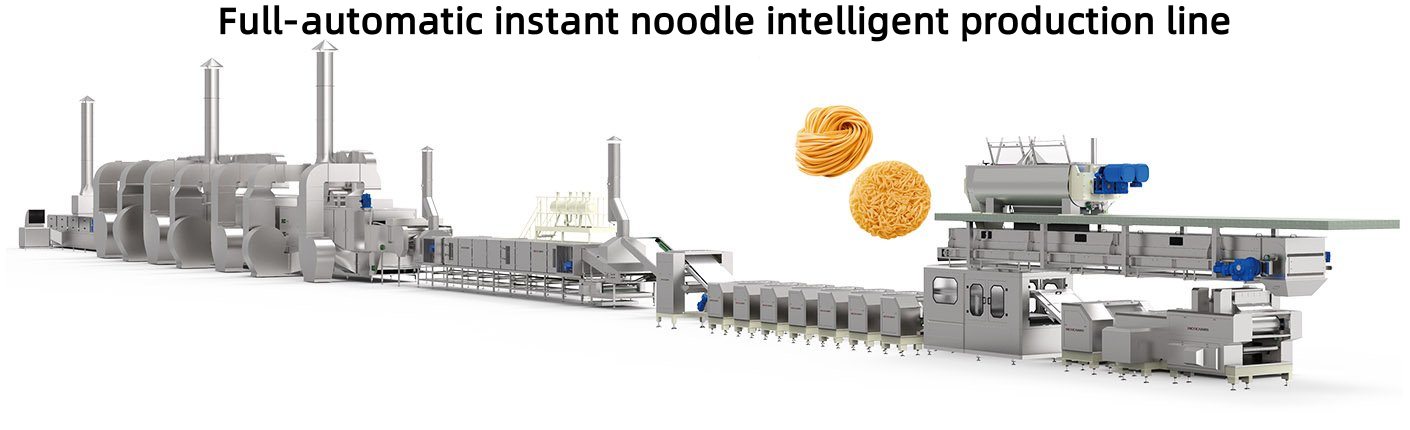

Our fully automated intelligent fried and non-fried instant noodle production line, developed independently by HICOCA, is the world’s only system capable of completing the entire process — from flour feeding to final product packaging and storage — all automatically. This means massive savings in labor and time, and a significant increase in production efficiency — that’s our core advantage.

Designed with advanced technology, compact structure, and stable performance, our instant noodle line requires just two operators to run the entire process. It’s smart, reliable, easy to maintain, and perfectly optimized to reduce costs while improving efficiency.

Standardized production process & intelligent control:

① Water & flour feeding → ② Dough mixing → ③ Dough aging → ④ Compound pressing → ⑤ Steaming & seasoning → ⑥ Cutting → ⑦ Frying / hot-air drying → ⑧ Cooling → ⑨ Sorting & conveying → ⑩ Automatic packaging

Powered by HICOCA’s self-developed control system, every step — from steaming and drying to cooling — is precisely managed. The result: consistently high-quality noodles with smooth texture, great elasticity, and excellent rehydration.

Optional configurations include single or multi-layer steamers, low-pressure steam sources, and sectional circulating drying systems, which ensure uniform drying, longer steaming time, and reduced energy consumption.

Our bottom-blow, top-suction cooling system efficiently discharges hot air, achieving superior cooling performance while improving the workshop environment.

Post time: Nov-20-2025