New Arrival China Dried Noodles Packaging Equipment - High Speed Automatic Noodle Weighing Machine – Hicoca

New Arrival China Dried Noodles Packaging Equipment - High Speed Automatic Noodle Weighing Machine – Hicoca Detail:

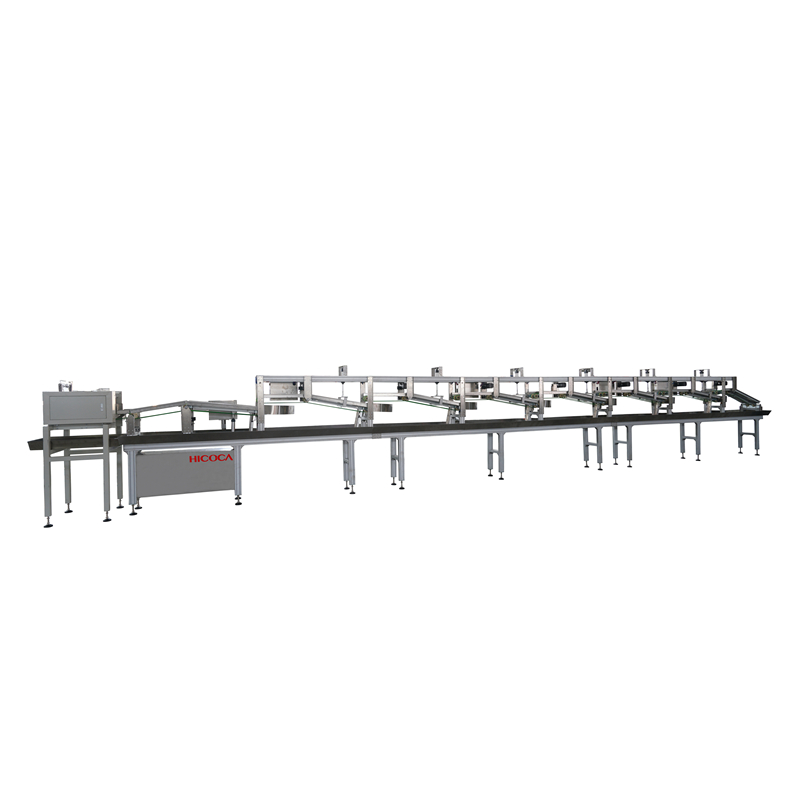

High Speed Automatic Noodle Weighing Machine

Application:

The equipment is mainly used for weighing long strips of food such as dry noodle, spaghetti, rice noodle, long pasta, etc. It can accurately weigh different weights according to requirements and cooperate with bundling machine, elevator, feeding system and packaging machine. It can be used alone or connected.

Technical Specification:

| Voltage | AC220V |

| Frequency | 50Hz |

| Power | 2KW |

| Weighing Range | 300~1000 ±2.0g, 50~500 ±2.0g |

| Weighing speed | 30-50 times/min |

| Dimension(L x W x H) | 3900 × 900×2200mm |

Highlights:

1. It can be used together with ordinary packaging machine and three-dimensional bag packaging machine, and the accurate weighing can be completed by the combination of rough and fine weighing.

2. With the unique design of automatic feeding system for fine weighing, the manipulator grabs materials from the rough weighing bin and automatically puts them into the fine weighing bin, which is 70% faster than that of ordinary weighing machine.

3. The elevated design facilitates people and logistics to pass through without obstacles, saves material and personnel flow time and speeds up the circulation efficiency of the workshop.

4. It is equipped with double feeding ports, which can complete the cooperation of the two feeding ports and the following conveying machines at the same time, so as to realize orderly and rapid automatic weighing.

Working conditions:

Site requirements: flat floor, no shaking or bumping.

Floor requirements: hard and non-conductive.

Temperature: -5~40ºC

Relative humidity: <75%RH, no condensation.

Dust: no conductive dust.

Air: no flammable and combustible gas or objects, no gas, which can make damage to mental.

Altitude: under 1000 meters

Ground connection: safe and reliable ground environment.

Power grid: stable power supplying, and volatility within +/-10%.

Other requirements: keep away from rodents

Related packing Line:

Product detail pictures:

Related Product Guide:

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for New Arrival China Dried Noodles Packaging Equipment - High Speed Automatic Noodle Weighing Machine – Hicoca , The product will supply to all over the world, such as: Istanbul, Nigeria, Thailand, We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.